Project Description

OIL WATER SEPARATORS

Oil separators are devices designed for the separation and capture of oil substances from wastewater.

USAGE

An oil water separator is a device designed to separate and collect oil products from wastewater of car washes, filling stations, car parks, street areas….

TECHNICAL CHARACTERISTICS

The oil separator is constructed as a monolithic concrete tank from waterproof concrete. The entrance into the oil water separator is enabled through a concrete shaft, a cast iron cover of Ø 600 mm according to the required load class (B125, D400) is placed on its top. The wastewater flows into the oil separator through an influent pipe. Inside of the tank there is technological equipment for wastewater purification, consisting of:

sedimentation tank

coalescent filter (1st purification level)

final oil purification filter (2nd purification level)

The design of the oil separator is based on the specific gravity difference between oil products and the wastewater. In the sedimentation tank, most of suspended solids settle together with the sludge and sand to the bottom of the sedimentation tank as a sediment layer. The oil products rise up to the water level, and the water is the middle layer between the oil products on top and the solids on the bottom. In case the wastewater purification level is required less than 0,5 or 0,1 mg/I NES, the final oil purification filter will be installed (2nd purification level).

The water sampling is carried out in an inspection well direct behind the oil water separator. Our oil separators meet standards according to STN EN 858-1 and STN EN 858-2. The output value of the oil products in the cleared water is from 5 mg/I NES to 0,1 mg/I NES.

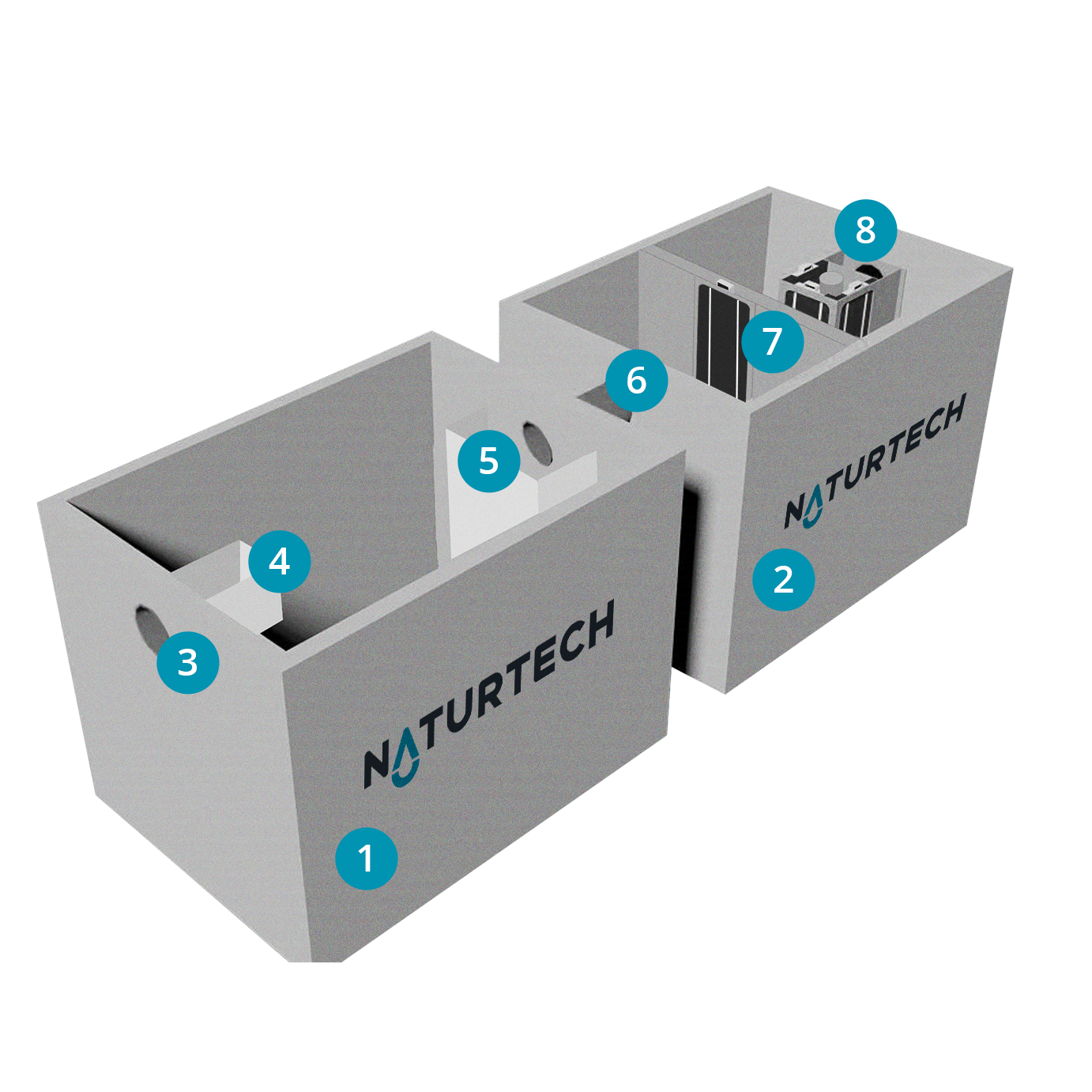

DESCRIPTION

1. Sedimentation Tank

2. Tank with Filters

3. Inlet

4. Inflow Barrier

5. Inflow Barrier

6. Connection Pipe

7. Coalescent Filter (1st Purification Level)

8. Final Oil Purification Filter (2nd Purification Level)

INSTALLATION

The oil separator is to be installed by means of the truck crane into a prepared excavation on the horizontal ground concrete with the sand bottom. Thickness of the ground concrete is specified by a structural engineer for each building object individually. In case of high groundwater level, the oil separator tank needs to be anchored.

FACILITY SERVICE AND MAINTENANCE

To assure long-life functionality of the oil separator, it is necessary to follow operating instructions, check the oil water separator on a regular basis and clean it as needed.