Project Description

WASTEWATER PUMPING STATIONS

A wastewater pumping station is a device designed to move wastewater to a sewerage system set higher. The wastewater lift stations are used to pump sewage water, stormwater and industrial water in order to overcome elevation differences on a gravity sewer system when gravity conditions are disadvantageous.

TECHNICAL CHARACTERISTICS

Pump shaft:

The pump shaft is a tank used to install technical devices for the wastewater pumping. Our company delivers mostly prefabricated concrete tanks, but it is possible to install the technology in plastic HDPE-tanks too. Our prefabricated concrete tanks are made from C30/37, C35/45 or C40/50 waterproof concrete (according to STN EN 206). They can be designed with a circular or square tank bottom depending of the tank accumulation capacity. Our shafts are constructed of one or more parts, depending of the shaft height. Butyl rubber is to be put between the individual shaft parts to ensure the joints waterproof. In the shaft wall, manholes can be made for an inflow pipe, water delivery pipeline and for electrical installation. Plastic stairs can be set in the shaft (according to STN EN 1917). There is a concrete cover plate with entry manholes on the shaft. Lockable composite, cast iron or steel covers according to the required load class (A150, B125, C250 or D400) are used to close the entry manholes.

Technology:

The lift station technology consists of pumps, duck foot bends, a hanging system and of (rustless, cast iron, PPR or HDPE) water delivery pipes with valves (ball check valve and plug valve). It is necessary to take into consideration input data (like Q=water discharge, H=height, sewage or rain wastewater) by technical design of pumps. We deliver pumps of renowned producers that meet all technical norms and standards and are certified for above mentioned wastewater types. The pumping shafts are equipped with a ladder and an assembly platform to handle with the pumps or valves safely and comfortably.

Electronic processing unit:

The run of the pumping station is controlled by an electronic processing unit and by floating switches that scan the height of the water-level in the pump shaft. The floating switches, which are placed in the pump shaft, activate the pumps according to the height of the water-level in the pump shaft. The lower floating switch scans the lowest water-level in the pump shaft, turns on and off the first pump to avoid its running without any water. The middle floating switch turns on and off the second pump. The upper floating switch signals an emergency water-level in the pump shaft. The electronic processing unit is equipped with visual and an acoustic signalization. The electronic processing unit controls the running of the pumps and changes them periodically – in this way both pumps work approximately the same time, what prolongs the service period for the oil change and their life-time too. The electronic processing unit is installed in a plastic switch box to be protected before various atmospheric actions. The electronic processing unit can be equipped with a GSM gateway or with a radio data transfer for a remote data transfer.

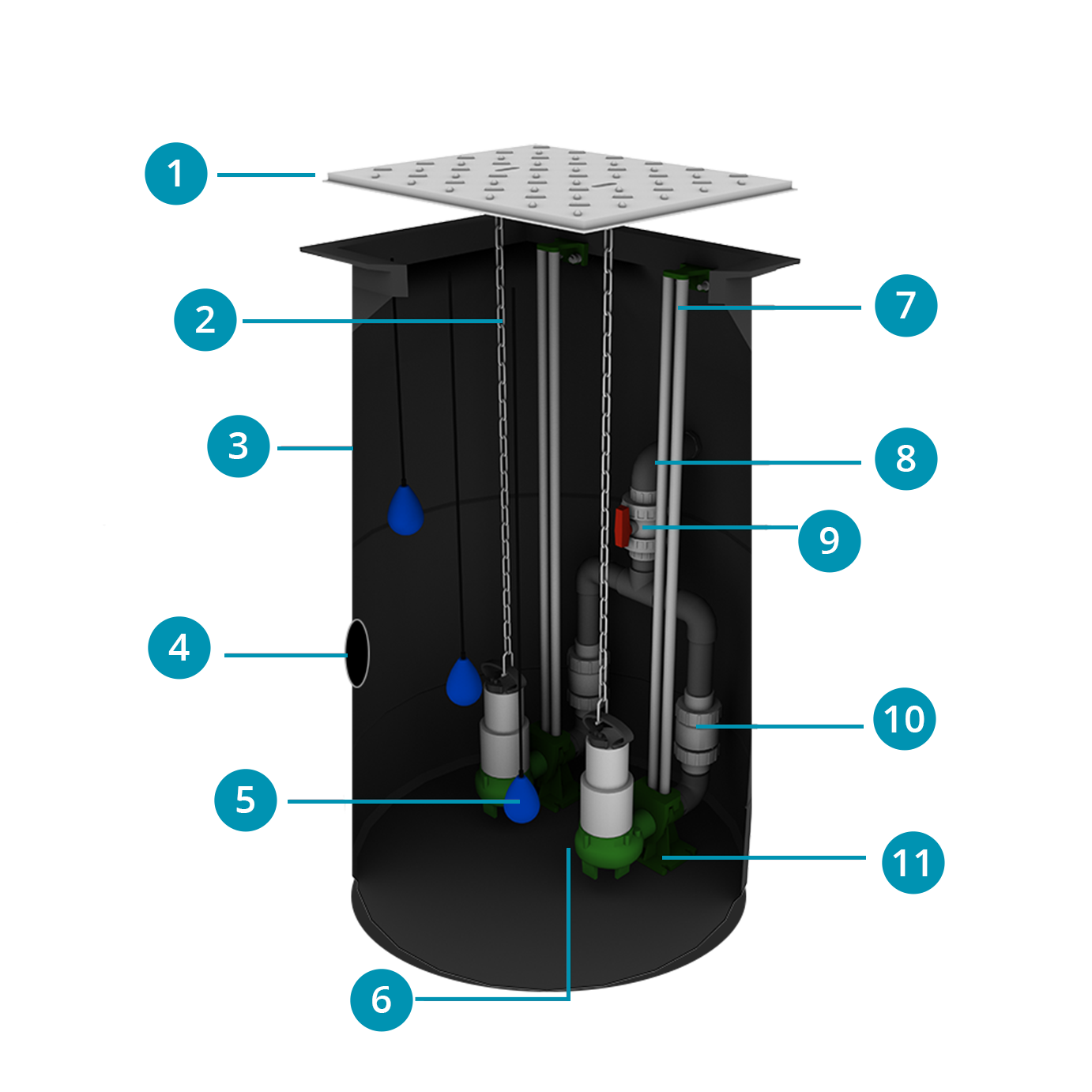

DECRIPTION

1. Manhole with Cover

2. Pump Lifting Chain

3. Underground Concrete Tank

4. Inlet

5. Floating Switch

6. Sludge Pump

7. Pump Rod

8. Water Delivery Pipe

9. Plug Valve

10. Ball Check Valve

11. Duck Foot Bend

FACILITY SERVICE AND MAINTENANCE

We ensure the warranty and after-warranty service as well as operation for our wastewater lift stations.